Non dubitant ad contactus cum opus nobis?

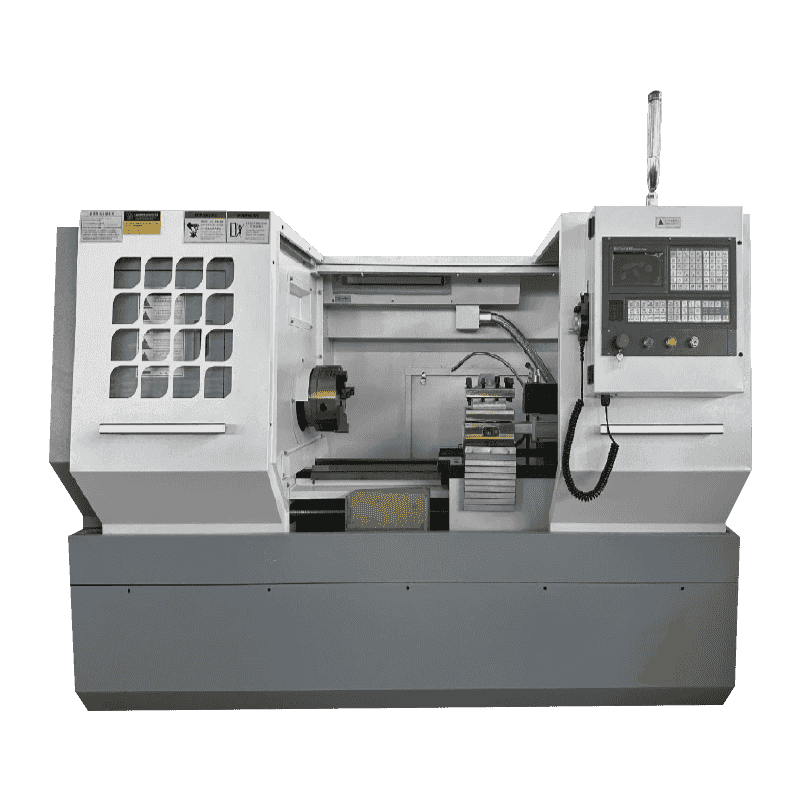

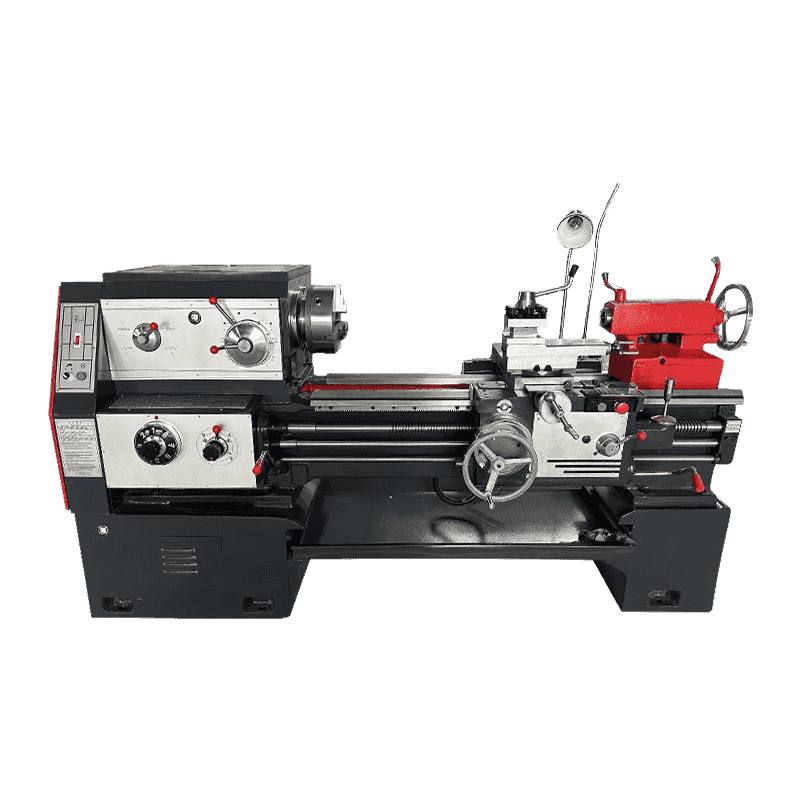

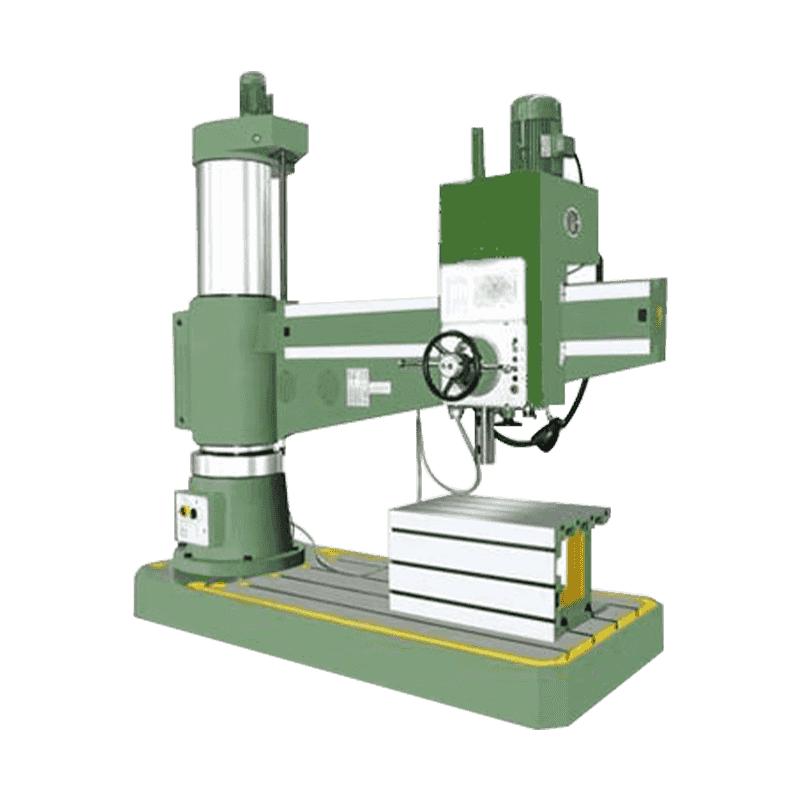

Horizontalis conversus Center Coolant Tank Tank: Fusce ut innovative SOLUTIO pro praecisione machining

2025.07.09

2025.07.09

News industria

News industria

I. opus principium productum

Innovative separatum refrigerationem ratio consilio Horizontal Tank Center Coolant Horizontal Tank mutata est structural conceptum de traditional conversus centrum. Hoc provectus apparatu totaliter separat secans fluidum repono ratio ex machina instrumentum corpus et perfectam et perfectam ex agentibus refrigerationem et ultimum praesidium per externa drawable coolant tank. In horizontali conversus centrum cum avidissimam coolant tank separat cutting fluidum alveus ex machina instrumentum corpus effectiving vitandum potentias corrosio periculum rate ex praecisione leakage elit. In independens aquam piscinam non solum auget altiore praesidium perficientur machina instrumentum, sed etiam servat machina instrumentum corpus siccum et mundus, extendens ministerium vitae apparatu.

Core opus principal--

Separatum Refrigerandam ratio: coolant tank to plene inclusum independens consilio coniungitur ad pelagus apparatus per a velox iungo, totaliter isolating in contactu inter cutting fluido et praecisione partibus machina instrumentum

Negative pressura circulationem technology: et aedificatum, in summus pressura sentinam coetus (pressura potest pervenire 20BBAR) cooperatur cum intelligentes fluxus imperium ratio ad consequi accurate partus et convaluisset de coolant

Tres-scaena filtration fabrica, continet crassum filtration, denique filtration et magnetica filtration unitates ut puritatem coolant

Temperature imperium moduli, instructa cum PID temperatus imperium ratio et calor exchanger ponere constant temperatus de coolant

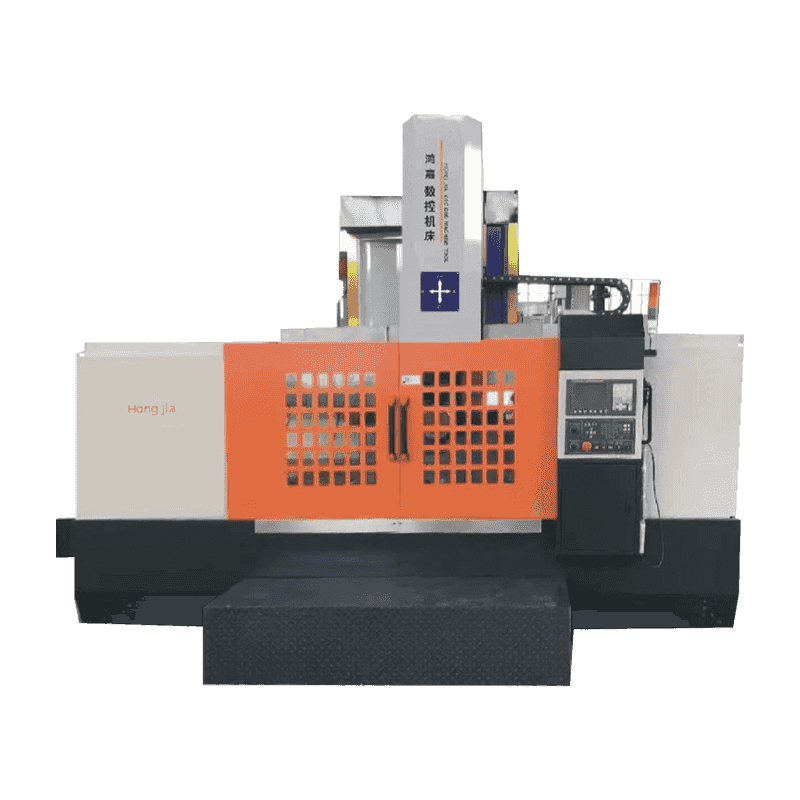

II. Product commoda

Hoc innovative Design Affert Unrececedentem perficientur emendationem et operationem et sustentacionem commodum est modernam praecisione machining, showing significant commoda in multiple dimensiones.

Comparatio Core Technology commoda:

| Euismod Indicatores | Traditional Horizontalis conversus centrum | Extractable Coolant Tank Model |

| Anti-corramen perficientur | Coolant contactus machina tool structure | Complete corporalis solitudo |

| PRAETERIENS | 800-1000 horis | MMD horas |

| Liquido replacement efficientiam | 4-6 horas / Tempus | 1.5 horas / Tempus |

| Accurate retention | Calibration required omnis VI mensibus | Sagaciter servetur pro XII mensibus |

| Industria consummatio gradu | Vexillum campester | Refrigerant ratio salvet XXX% navitas |

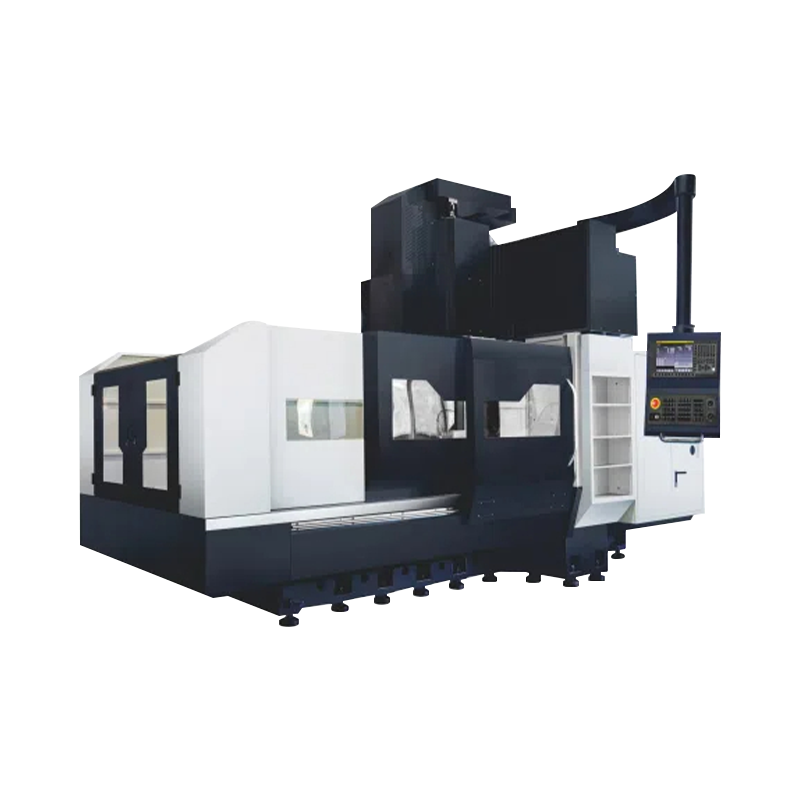

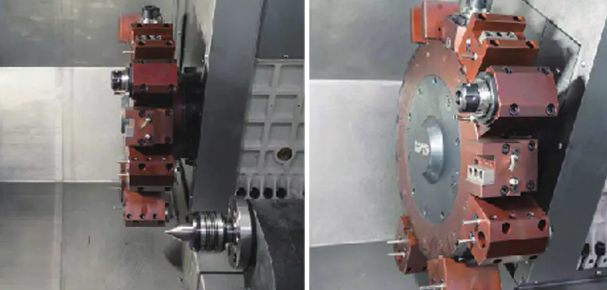

III. Technological Breakthrough de chip remotionem ratio

Advanced chip remotionem ratio est alius major technica highlight huius apparatu. Et innovative consilio perfectly solvit quaestionem de chip administratione in praecisione machining.

Technical Analysis de chip remotionem system--

Multi-gradu genus mechanism: Lorem chip classificationem per vibrationem protegendo pneumatic

Intelligentes Sensu technology: Built-in Visual System Monitors chip Morphology in realis et statim accomtat chip remotionem parametri

Minimum-strepitus operatio Design: Hydraulica damping sonus-absorbing materiae sunt, et opus strepitu est ≤68db

Magna-capacity processus: maximum chip remotionem volumine pervenit 150kg / h, quae est idoneam ad gravibus-officium cutting conditionibus

Chip remotionem processus--

Negative Press Collection in Cutting Area → Prima magnetica Separationem → Vibration protegendo et transientes → Spiritus PRAECEPTRIFICATIO ad chip collectio vehiculum → automatic metum promptum Purgato

IV. Ritus specifications et sustentationem Points

Ad curare optimum perficientur apparatu et extend ad ministerium vitae, scientific operationem et sustentacionem procedendi oportet sequebatur.

- Pre-startup inspectionem:

Confírma quod coolant tank est plene in locum et clausum

Reprehendo quod chip remotionem pipe non deformatur vel obstructus

Quin quod liquida gradu sensorem munera Northmanni

- Cras in operationem:

Coolant temperatus est regitur XXV ± II ℃

Chip remotionem ratio onus current ≤80% of rated valorem

Abnormes vibrationis (> 2mm / s) statim prohibere machina ad inspectionem

- Daily Sustentationem:

Mundare chip remotionem currus cotidie (residue <1/3 Volume)

Reprehendo in filter pressura difference weekly (> 0.3MPA oportet reponi)

Reprehendo coolant concentratione menstrua (servetur ad 4-6%)

Commune Troubleshooting:

| PHATOMENTUM | PRAETEREO | Solution |

| Coolant terrorem | Level sensorem contaminari | Clean specillum cum Vocatus Cottonus |

| Pauper chip remotionem | Chip involvit circa spiralem hastile | Reverse ad X seconds et deinceps |

| SCRIPTIO | Ferentem caret oleum | Addere summus temperatus extremum pressura uncto |

| SUBITIO | Filter capax | Reponere filter elementum (pressura differentia> 0.4MPA) |